R&D

The driving force behind process improvement and product innovation

Upco®’s centre of research and development is located within its headquarters in Heroldstatt, Germany. This research center focuses mainly on the development of new coatings and constantly collaborates with the two research and development centers of the Coveme Group located in Italy and China.

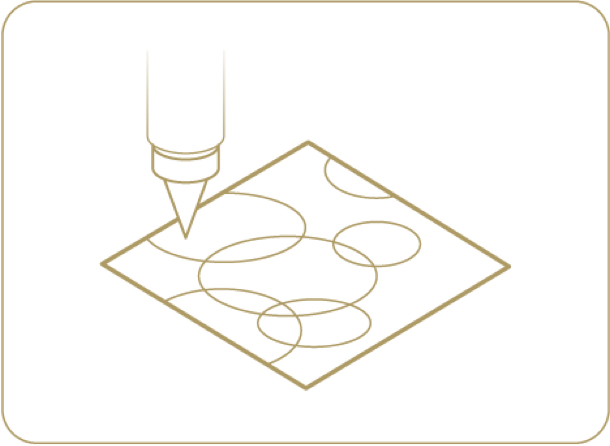

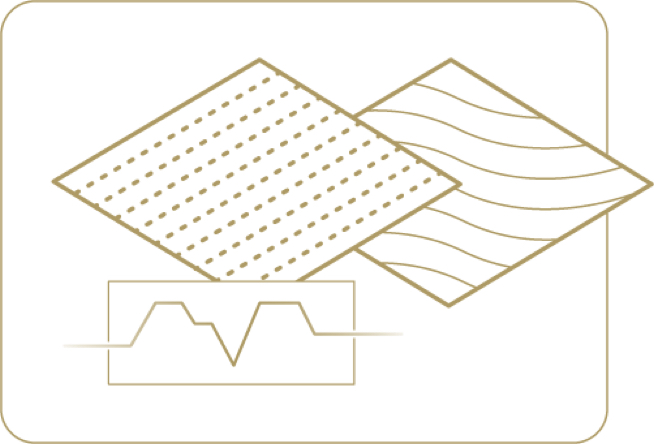

The aim of Upco®’s R&D activities is to constantly improve processes and materials, to anticipate the demands of our clients and trends of the industry, and to turn product innovations into industrial solutions. To test and analyze the properties of a lacquered surface the most advanced analytical instruments are used. The result are continuous new features of our products and their optimization, with a particular focus on the development of new coatings that confer high mechanical and chemical resistance to the surfaces they are applied to. The R&D lab has a pilot line installed where production processes are simulated. In the Upco® laboratories the coatings are applied on a wide range of flexible substrates, then analysed and tested with the focus on the final application in an industrial roll to roll process. Besides the optimization of the coating material for matt and gloss effects, another important target are the funcional aspects of the surface such as:

- Hydrolysis resistance

- Release properties

- UV resistance

- Printability

- Scratch resistance

- Anti-microbial properties

- Anti-finger print properties